Monday, December 24, 2012

Saturday, December 22, 2012

Planes

Last weekend I picked up some stuff that I have had in storage for the past years. There I found a couple of planes that I almost forgot about. I bought them at a flea market around 15 years ago and have never used them.

The blades need to be sharpened a little and then they are good to go.

Snowing again today and Christmas is approaching.

Top right: Rabbet plane / Top left: Some sort of profile plane, see below / Middle: Block plane with an Eskilstuna blade (very famous in Sweden) / Bottom: Block plane with a convex bottom and blade

The blades need to be sharpened a little and then they are good to go.

Profil shape on one of the planes, maybe for planing picture frames or something similar. How do you sharpen that kind of blade?

Snowing again today and Christmas is approaching.

Wednesday, December 19, 2012

Cleats II

Cut the cleats, this would have been so much easier if I had a bandsaw especially the small fiddly cuts I will do next.

Time today: 20 minutes

Friday, December 14, 2012

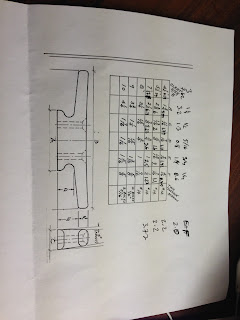

Cleats I

Started working on making cleats. The will be used to secure the halyards on the masts and as mooring cleats on the fore and aft decks.

Found a model on the intranet that I like.

And a piece of oak left over from something.

Drilled holes.

Still need to make the piece trapezoidal (ref drawing above) on the table saw, cut them out and shape them.

Time today: 30min

(p.s this is my post number 200!!!)

Found a model on the intranet that I like.

And a piece of oak left over from something.

Drilled holes.

Still need to make the piece trapezoidal (ref drawing above) on the table saw, cut them out and shape them.

Time today: 30min

(p.s this is my post number 200!!!)

Saturday, December 1, 2012

Foot supports

Decided to glue the foot supports tonight. I have not unpacked the epoxy yet so I used an normal wood glue (vinylacetate homopolymer emulsion stabilised with polyvinylalcohol????) intended for outdoor use. Should be fine as this piece will not be immersed in water, in addition it cures much quicker than epoxy.

Time today: 15 min

Getting ready

Glue applied. Instead of spreading the glue evenly I put the two pieces on top of each other and slid them around a little to make sure I have an even layer of glue.

Pressure applied! Glue is dried within an hour.

Time today: 15 min

First snow

We had the first snow of the season this week. After the weekend apparently it is supposed to get real cold so there may be more.

Sunday, November 25, 2012

Cutting seat

Cut out the foot brace pieces and the rowing seat. Still do not have enough space in the basement so I had to take the workshop outside, a bit cold but at least above freezing.

Did not have time for much more since the kids found a dead fish on the beach and I was needed for the funeral.......

Time today: 30 min

Getting started

All done, next stop is glue (next week?)

Time today: 30 min

Monday, November 19, 2012

Back to the boat

Back to doing some "building" again, even tough the pace will be slower this winter it is nice to focus a little on the boat again. Started to work on the loose pieces for rowing; the seat and the foot support.

The cutting will have to wait until next weekend as I am off on another trip tomorrow.

Time on Sunday: 1h

The sketch

The templates

Drawn up and ready for cutting

Time on Sunday: 1h

Saturday, November 17, 2012

Wednesday, October 31, 2012

Getting ready for winter

Prepped the boat for winter. I bought a new big tarp instead of the two old small crappy once. Quite a lot of water had leaked in the joint despite a 40 cm overlap.

So we cleaned the boat and got the new tarp on. Added some more wood to support the tarp (avoiding water puddles) and provide ventilation openings.

Ended the day by carving the first pumpkin in my life!

Crew hard at work

So we cleaned the boat and got the new tarp on. Added some more wood to support the tarp (avoiding water puddles) and provide ventilation openings.

After a job well done!

Ended the day by carving the first pumpkin in my life!

HAPPY HALLOWEEN!!!!!

Sunday, October 14, 2012

Material costs

Thought I should look into the material costs today.

I ordered the frame kit from Fyne, something that shortened my building time but increased the cost. Another thing that drastically could have saved me some money was the Epoxy. I started out buying West Epoxy which is hard to find and very expensive in Poland, eventually I found a local manufacturer LaminoPol which had a very nice product at a third of the West price..... So had I gone local from the start I would have saved almost 300Euro!!!

So these where the main parts of the material cost:

Plywood: 300Euro (I bought too much as I did not need ply for the frames)

Frame kit: 710Euro

Solid wood: 660Euro (ready cut and planed to the right dimensions)

Epoxy: 680Euro (still have around 4 liters left which will be plenty for he remaining jobs)

Paint: 150Euro

So a grand total of: 2500Euro or about 3200USD

I am happy this was spread out over almost a whole year!

I ordered the frame kit from Fyne, something that shortened my building time but increased the cost. Another thing that drastically could have saved me some money was the Epoxy. I started out buying West Epoxy which is hard to find and very expensive in Poland, eventually I found a local manufacturer LaminoPol which had a very nice product at a third of the West price..... So had I gone local from the start I would have saved almost 300Euro!!!

So these where the main parts of the material cost:

Plywood: 300Euro (I bought too much as I did not need ply for the frames)

Frame kit: 710Euro

Solid wood: 660Euro (ready cut and planed to the right dimensions)

Epoxy: 680Euro (still have around 4 liters left which will be plenty for he remaining jobs)

Paint: 150Euro

So a grand total of: 2500Euro or about 3200USD

I am happy this was spread out over almost a whole year!

Monday, October 1, 2012

The vikings are coming

Went to a Viking fair organized by the local viking society, Alsnu. The weather was crap but the kids got to bake bread, shoot bow & arrow and listen to Aesir stories, I focused on the boats. I actually forgot to take pictures of anything else...

Monday, September 24, 2012

Time accounting III

The boat is in Sweden and I am busy with work and unpacking boxes. So I thought it may be time to look into how I have spent my time, by looking back at the milestones.

Start of build: 29/10-2011

Strongback built: total time 15h

Frames done: 10/12 total time 31h (I had the frame kit so if someone is building from scratch you should probably add another 30h)

Keel (bottom) laid: 17/12 total time 50.5h

Frames installed: 17/1-2012 total time 82.5h

Stringers installed: 29/1 total time 113h

Planking done: 22/3 otal time 209.5h

Bottom painted and right way up: 29/6 total time 297h

Decks in place: 7/9 total time 371.5h

Hull done (almost): 12/9 total time 387h

What is left to be done is some more painting, that I hope to have done before it gets to cold, building the masts and oars. So my initial estimate of 400h is not that far of.

Building will slow down for winter now (I doubt there will be time to launch her before it gets too cold) so the update frequency of the blog will also slow down. I will post when something happens and there will also be a a few posts about cost, tools, the odd nice boat I run across etc too keep the blog going until launch day.

By the way I just past 8000 page views the other day!!

Start of build: 29/10-2011

Strongback built: total time 15h

Frames done: 10/12 total time 31h (I had the frame kit so if someone is building from scratch you should probably add another 30h)

Keel (bottom) laid: 17/12 total time 50.5h

Frames installed: 17/1-2012 total time 82.5h

Stringers installed: 29/1 total time 113h

Planking done: 22/3 otal time 209.5h

Bottom painted and right way up: 29/6 total time 297h

Decks in place: 7/9 total time 371.5h

Hull done (almost): 12/9 total time 387h

What is left to be done is some more painting, that I hope to have done before it gets to cold, building the masts and oars. So my initial estimate of 400h is not that far of.

Building will slow down for winter now (I doubt there will be time to launch her before it gets too cold) so the update frequency of the blog will also slow down. I will post when something happens and there will also be a a few posts about cost, tools, the odd nice boat I run across etc too keep the blog going until launch day.

By the way I just past 8000 page views the other day!!

Sunday, September 16, 2012

Crew inspection

Today my rowing crew (the kids) got their first chance to inspect their vessel. Happily they seemed pleased and are already planning the first camping trip.....

Friday, September 14, 2012

Waiting for the ferry

So far so good, only had to stop once to tighten a loose strap. Need to by a new tarp this one is crap (but cheap crap) too thin and flaps about all the time.

Thursday, September 13, 2012

Left overs

This is what is left over of the ply and wood I bought (except the wood for masts and oars that I bring with me to Sweden)

Wednesday, September 12, 2012

Out of the garage

Brought some friends from the office to bring "Small Wind" out of the garage. Real sunlight gives you a much better view, to how lovely the lines of this design is but also all the imperfections (There is some (a lot) of touch up to be done on the painting....)

Time today: 1.5h

Coming out of the garage, she is surprisingly light (now I believe the 100kg specified by John)

Turning around, and you can see my tarp support

Going on the trailer

Yours truly supervising

Fine tuning supports

Nice!!??!!

All wrapped up and ready to go!

Tuesday, September 11, 2012

Painting done (almost)

Got up early again to do some more painting before work.

After work we adjusted the supports on the trailer, fine adjustments will be done when she is loaded tomorrow.

Then it was time for painting, so now the decks and seat tops have three coats. Seat fronts, bottom and sides have two coats. Cargo area, centerboard casing and under deck has one coat. It looks nice but there will be some more painting to be done when I get to Sweden.

The thing on top of the centerboard case is a pieces of wood and some string to keep the centerboard up when we lift her tomorrow. The stick thing on top of the strong box is a tarp support to divert rain water when we drive to Sweden, you will see what I mean tomorrow or the next day.

Time today: 3h

In the morning

After work we adjusted the supports on the trailer, fine adjustments will be done when she is loaded tomorrow.

Then it was time for painting, so now the decks and seat tops have three coats. Seat fronts, bottom and sides have two coats. Cargo area, centerboard casing and under deck has one coat. It looks nice but there will be some more painting to be done when I get to Sweden.

In the evening

The thing on top of the centerboard case is a pieces of wood and some string to keep the centerboard up when we lift her tomorrow. The stick thing on top of the strong box is a tarp support to divert rain water when we drive to Sweden, you will see what I mean tomorrow or the next day.

Time today: 3h

Monday, September 10, 2012

Grey paint

Got up early this morning to finalise the coamings, i.e removed the stitches, faired the front end and added the final fillets.

Tonight I sanded the coaming fillets and the deck again, cause I really like sanding.....

Then it was time for paint, could not finish the first coat since the filters for my mask ran out of the good stuff so I started breathing the paint fumes. New filters tomorrow. Just two pictures today, it is amasing what a coat of paint can do.

Time today: 3h

Tonight I sanded the coaming fillets and the deck again, cause I really like sanding.....

Then it was time for paint, could not finish the first coat since the filters for my mask ran out of the good stuff so I started breathing the paint fumes. New filters tomorrow. Just two pictures today, it is amasing what a coat of paint can do.

After....

....& before

Time today: 3h

Sunday, September 9, 2012

Coaming Pt II

Sanded the deck for glueing on the coaming and painting.

Glued the coaming in place. Had a bit of a mishap when the sand bucket that held the forward end down tipped over. Well we got that sorted and tomorrow there will be some vacuuming to be done.

Finally I installed the oar lock "blocks".

Time today: 3h

Glued the coaming in place. Had a bit of a mishap when the sand bucket that held the forward end down tipped over. Well we got that sorted and tomorrow there will be some vacuuming to be done.

Some sand left on the bottom of the boat

A bit of stitch n glue up front

Made them a bit higher than normal since I am quite big...

Saturday, September 8, 2012

Coaming

Today was the big day of the coaming, started out making a cardboard template.

From the cardboard I could cut the real pieces out of 6mm ply.

Then it was time for dinner, at Taverna Orlowska.

After dinner we added some glue to two areas of the deck where it had not attached the the boat, by drilling holes and inserting glue through a syringe. Finally we filled the gap between the deck and gun wale with glue, to make a smooth transition.

Time today: 5h

From the cardboard I could cut the real pieces out of 6mm ply.

Dry fitting

A bit of stich & glue up front

Scarfs ready for glueing

Coamings glued! Yes, the bench is a mess.

Then it was time for dinner, at Taverna Orlowska.

Nice!

After dinner we added some glue to two areas of the deck where it had not attached the the boat, by drilling holes and inserting glue through a syringe. Finally we filled the gap between the deck and gun wale with glue, to make a smooth transition.

Time today: 5h

Subscribe to:

Comments (Atom)